For electrical and electronic applications requiring extensive machining, copper-tellurium (CuTeP, Te: 0.4-0.7%) and copper-sulphur (CuSP, S: 0.2-0.7%), with machinability indexes of 80% and an IACS of 93-94%, are the ideal choices. They are called free machining coppers.

History

CuTeP (C109) and CuSP (C111) first appeared in British Standards in BS 2874:1962 Rod for Free Machining Purposes and in BS 2873:1969 Wire for General Purposes.

In European Standards, CuTeP (CW118C) and CuSP (CW114C) appear in PD CEN/TS 13388 Copper and Copper Alloys – Compendium of Compositions and Products.

Heat Treatment

CuTeP and CuSP cannot be hardened by heat treatment; they may be stress relieved at 225-275oC.

Properties

CuTeP and CuSP have the same range of properties as below:

- Tensile strength: 250-360 N/mm2

- 0.2% Proof strength: 180-300 N/mm2

- % Elongation: 7-2

- Hardness (HV): 65-130

- Electrical conductivity: 93-94% IACS

- Thermal conductivity: 347-370 W/moC

Fatigue Resistance

For a CuTeP rod with a tensile strength of 275 N/mm2, the fatigue strength measured by the rotating beam test is 97 N/mm2 at 106 cycles. The fatigue strength is important where high insertion loads or high cycles are required such as in socket connectors for high voltage power source.

Fabrication

| Process | Rating |

| Cold formability | Good |

| Hot formability | Good |

| Soldering | Excellent |

| Brazing | Good |

| Oxyacetylene welding | Not recommended |

| Gas shield arc welding | Not recommended |

| Resistance welding | Not recommended |

Machining

Both alloys with machinability indexes of 80% (free-machining brass sets the standard with a value of 100%) are superior to pure copper in all applications where products are drilled, turned or machined.

Efficiency on both manual and automatic product lines can be several times higher than that of pure copper which has an index of 20%, and also results in much lower tool wear. In addition, the surface finish of these alloys is superior to that of pure copper. A good surface finish is important in plating and soldering and in MIG welding nozzles, as a smooth surface resists spatter build-up.

The reason for the good machinability is explained by the microstructures which show tiny particles of Cu2Te in CuTeP and Cu2S in CuSP in the copper matrix. These act as chip breakers leading to short chips, which fly off quickly, allowing a much higher machining speed than is possible with pure copper and resulting in a more cost-effective product for the designer.

Scrap Disposal

When working with CuTeP, great care must be taken to strictly segregate copper tellurium scrap. Tellurium copper scrap should not be mixed with normal unalloyed scrap since it is important to avoid the presence of tellurium in other copper alloys.

Resistance to Corrosion

Both alloys, as all copper alloys, have good resistance to atmospheric corrosion.

Resistance to Softening

This may be defined as the temperature at which approximately 10% loss of strength occurs. For both alloys this is about 150oC.

Applications

When a component is specified to be made from a free-machining copper, it is often dual certified which means that either CuTeP or CuSP may be used, although CuSP may be a more cost effective choice for certain applications.

The combination of excellent machinability, easy forming, good corrosion resistance and high electrical and thermal conductivity makes CuTeP and CuSP the ideal choices for the following:

- Relay parts

- Electrical switches

- Circuit breaker terminals

- Electrical connectors

- Transistor bases

- Switch gear parts

- Soldering and welding tips

- Bolts

- Studs

- Contacts

- Clamps

- Pins

- Magnetron bodies and coolers

- Socket connectors

- Plasma cutting electrodes and nozzles

- Laser nozzles

Available Forms

Both alloys are available as hollow rod, hexagonal, round and square rod, tube and wire. Profiles may be available on request to the manufacturers.

Specifications

Below are the specifications for Europe and USA. Note that for USA equivalents, some compositions are not identical. For equivalent standards from other countries visit the Copper Key website.

- UK: C109 (CuTeP), C111 (CuSP) (British Standard BS designation). UK Standards are superseded by European Standards.

- Europe: CW118C (CuTeP), CW114C (CuSP) (European Standard EN designation).

- USA: C14510 (CuTeP), C14700 (CuSP) (American Society for Testing and Materials ASTM designation).

Application Example 1: High Voltage Copper-tellurium Pin Bodies

These are able to be machined to ± 0.025mm using copper-tellurium. The smooth surface allows these components to be easily nickel-plated.

High voltage copper-tellurium pin bodies (Courtesy of KME Germany)

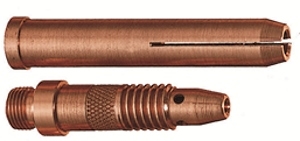

Application Example 2: MIG Welding Gun Nozzle Tips

Metal inert gas (MIG) welding is a welding process in which an electric arc forms between a consumable wire electrode and the workpiece which heats the metal causing them to melt and join. The nozzle tip transmits electrical energy to the electrode which passes through it and directs it to the weld area. It must be very accurately machined since it must allow the electrode to pass while maintaining electrical contact. In addition, the smooth surface of the tip resists spatter build-up. This is why copper-tellurium is ideal for this application.

MIG welding gun nozzle tips (Courtesy of KME Germany)

Quick Facts

Properties

The alloys have the following combination of properties:

- Tensile strength: 250-360 N/mm2

- 0.2% Proof strength: 180-300 N/mm2

- % Elongation: 7-2

- Hardness (HV): 65-130

- Electrical conductivity: 93-94% IACS

- Thermal conductivity: 347-370 W/moC

Applications

- Relay parts

- Electrical switches

- Circuit breaker terminals

- Electrical connectors

- Transistor bases

- Switch gear parts

- Soldering and welding tips

- Bolts

- Studs

- Contacts

- Clamps

- Pins

- Magnetron bodies and coolers

- Socket connectors

- Plasma cutting electrodes and nozzles

- Laser nozzles

Available Forms

Both alloys are available as hollow rod, hexagonal, round and square rod, tube and wire. Profiles may be available on request to the manufacturers.

Comments

0 comments

Please sign in to leave a comment.