Copper-iron (C19210) is a heat treatable, very low iron alloy (0.05 to 0.15%). It is stronger and harder than pure copper with slightly lower electrical conductivity.

History

This alloy was developed in the 1960s by Olin Brass in the USA for electronic and electrical applications as an alternative to pure copper. There is no European or British standard for this alloy.

Heat Treatment

The precipitation heat treatment involves heating the alloy to 800 to 900oC and water quenching. This is called solution treatment and the alloy is in its softest condition.

Subsequent precipitation (age) hardening at lower temperatures of 425 to 500oC results in the formation of finely dispersed iron precipitates in the alpha matrix; these are responsible for the increased strength and hardness.

The alloy may be stress relieved at 200 to 300oC.

Properties

The alloy has the following combination of properties:

- Tensile strength: 345-520 N/mm2

- Proof strength: 330-480 N/mm2

- % Elongation: 15-2

- Hardness (HV): 80-160

- Electrical conductivity: 80-90% IACS

- Thermal conductivity: 350-364 W/moC

Fabrication

| Process | Rating |

| Cold formability | Excellent |

| Hot formability | Excellent |

| Soldering | Excellent |

| Brazing | Good |

| Oxyacetylene welding | Good |

| Gas shield arc welding | Not recommended |

| Resistance welding | Good |

Machining

This is rated at 18% which is fair. Free-machining brass is 100%.

Resistance to Corrosion

Copper-iron C19210 has good resistance to corrosion in industrial and marine atmospheres. It is insensitive to stress corrosion cracking. However, it is susceptible to attack in the presence of ammonia, sulphur, hydrogen sulphide and mercury.

Stress Relaxation

This is a decrease in stress under constant strain, typically observed in steel bolts in turbine casings at high temperatures which must be regularly tightened.

For copper alloys used in electrical contacts, it is important to maintain good contact force throughout the functional life of the product and have good resistance to stress relaxation.

One indication of stress relaxation resistance may be obtained by measuring the % of stress which is retained as a function of temperature and time.

Results on test pieces for this alloy show that 70% of the applied stress (80% of the proof stress) remained after 3000 hours at 120oC. This is useful information in the design of contacts, connectors, springs, relays and leadframes.

Applications

The combination of high electrical and thermal conductivity, higher strength than pure copper, good stamping formability, good solderability and platability, make this alloy ideal for the following applications.

- Lead frames

- Connectors

- Leaf springs for relays

- Stamped bent parts

- Car electrics

- Heat sinks

- Terminals

- Contacts

Available Forms

C19210 is available as strip.

Specifications

Below are the specifications for US and Asia. For equivalent standards from other countries visit the Copper Key web-site.

- USA: C19210 (American Society for Testing and Materials ASTM designation).

- Japan: C1921 (Japanese Industrial Standards JIS designation).

Further information on copper-iron C19210, and other conductivity materials, is available at the Copper Alloys Knowledge Base.

Application Example 1: Connectors

Copper has many advantages as a connector material and is present in nearly all electrical connector applications.

The example shown is a blade and block or spade connector. Wires are connected to the blade and block by crimping; this is where the high ductility of the alloy is an advantage. This type of contact is typically used in automotive applications and must withstand mechanical vibration, corrosion from road salts, exposure to fluids from lubricating oils, high pressure water jets and outdoor and under hood temperature extremes.

The high conductivity, high ductility and good corrosion resistance make C19210 an ideal choice for this application. They are usually plated with nickel or noble metal according to the application.

Blade and block connectors

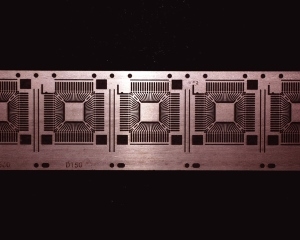

Application Example 2: Lead Frames

The main application for C19210 is lead frames. This is because of its very high electrical and thermal conductivity, ease of soldering and plating.

Lead frame (Courtesy of Wieland Werke).

Quick Facts

Properties

At room temperature the alloy has the following combination of properties:

- Tensile strength: 345-520 N/mm2

- Proof strength: 330-480 N/mm2

- % Elongation: 15-2

- Hardness (HV): 80-160

- Electrical conductivity: 80-90% IACS

- Thermal conductivity: 350-364 W/moC

Applications

- Lead frames

- Connectors

- Leaf springs for relays

- Stamped bent parts

- Car electrics

- Heat sinks

- Terminals

- Contacts

Available Forms

- Strip

Comments

0 comments

Article is closed for comments.