Phosphorus Deoxidised Tough Pitch Copper (Cu-DLP) is a general purpose tough pitch, phosphorus deoxidised copper, within which the residual phosphorus is maintained at a low level (0.005-0.013%) to achieve a good electrical conductivity. It has good thermal conductivity and excellent welding and soldering properties.

History

The term ‘tough pitch’ originates from the time when molten copper, after refining, was cast into ingot moulds. During refining the copper was oxidised to remove impurities then reduced by hydrogen to give the correct oxygen level. To monitor this process, a small sample was taken and the solidification surface observed. If the surface sunk there was too much oxygen; if it was raised there was too much hydrogen. If it was level (correct pitch), the oxygen was correct and the properties good; in other words ‘tough’, hence tough pitch.

The oxygen which is left in the tough pitch copper is removed by phosphorus which is the most commonly used deoxidant for copper but it does have a deleterious effect on the electrical conductivity which will be around 90% IACS with 0.013% phosphorus but higher at 98% IACS with 0.005% phosphorus.

Heat Treatment

It may be necessary to stress relieve Cu-DLP to reduce the possibility of distortion or cracking after machining or cold working. This may be done at 150 to 200°C. This does not soften the copper, if this is required then a full anneal at 400 to 650°C is needed. Copper cannot be hardened by heat treatment. It does not become harder with time. It does not have a ‘shelf life’.

Properties

A summary of the properties from the annealed (soft) to the hard condition is shown.

- Tensile strength: 220-385 N/mm2

- Proof strength: 60-325 N/ mm2

- % Elongation: 55-4

- Hardness (HV): 45-155

- Electrical conductivity: 90-98% IACS

- Thermal conductivity: 350-365 W/m°C

Fabrication

| Process | Rating |

| Cold formability | Excellent |

| Hot formability | Excellent |

| Soldering | Excellent |

| Brazing | Excellent |

| Oxyacetylene welding | Fair |

| Gas shield arc welding | Excellent |

| Resistance welding | Not recommended |

This copper does not suffer from steam (hydrogen) embrittlement when heated in a hydrogen (reducing) atmosphere.

Machining

Cu-DLP, like other pure coppers, cannot be regarded as a free-machining material, yet it is not difficult to machine, especially in the work-hardened condition, and has a machinability rating of 20% (free-machining brass is 100%).

Resistance to Corrosion

All coppers corrode at negligible rates in unpolluted air and water due to the formation of a protective oxide surface layer. Copper artefacts have been found in nearly pristine condition after being in the earth and under the sea for thousands of years. However, copper is susceptible to more rapid attack in the presence of ammonia, sulphur, hydrogen sulphide and mercury.

Resistance to Softening

Softening is time and temperature dependent and it is difficult to estimate precisely the time at which it starts and finishes. It is usual, therefore, to consider the time to ‘half-softening’, i.e. time taken for the hardness to fall by 50% of the original increase in hardness caused by cold reduction. In the case of Cu-DLP, this softening occurs at temperatures above 150°C. It has been established experimentally that such copper would operate successfully at a temperature of 105°C for periods of 2-25 years, and that it could withstand short-circuit conditions as high as 250°C for a few seconds without any adverse effect.

Creep

Creep is slow deformation of a material with time at temperature and must be allowed for in the design of any component above room temperature.

Cu-DLP does not creep at room temperature (unlike high conductivity aluminium) under normal stresses. However, creep must be considered in the temperature range above 150°C. However, this temperature is well above the usual operating temperature of applications such as busbars.

Applications

Cu-DLP has a combination of weldability and conductivity making it ideal for the following applications:

- Cable strip

- Welded or brazed busbars

- Tubular busbars

- Lead frames for power semi-conductors

- Resistance welding equipment

Available Forms

Cu-DLP is available as bar, extrusions, forgings, plate, sheet, strip, tube and wire.

Specifications

Below are the specifications of Cu-DLP for Europe, US and Asia. Note that for USA and Asia, some compositions are not identical. For equivalent standards from other countries visit the Copper Key website.

- Europe: CW023A (Cu-DLP) (European Standard EN designation).

- USA: C12000 (American Society for Testing and Materials ASTM designation).

- Japan: C1201 (Japanese Industrial Standards JIS designation).

Further information on Cu-DLP, and other conductivity materials, is available at the Copper Alloys Knowledge Base.

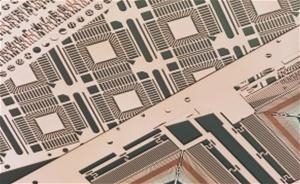

Application Example 1: Lead Frames

Lead frames connect the wiring from electrical terminals on the semiconductor surface to the large-scale circuitry on electrical devices and circuit boards. Etching or stamping is used to make the basic shapes of these lead frames which are then bonded to silicon chips at temperatures as high as 500°C. The pins are then bent to make the contact legs accurately. The material is chosen to meet the process requirements and still be reliable when fitted and in service.

Copper lead frame (Courtesy of Wieland-Werke).

Application Example 2: Waveguide Assembly

A waveguide is a special form of transmission line consisting of a hollow, metal tube. Waveguides may be thought of as conduits for electromagnetic energy, the waveguide itself acting as nothing more than a “director” of the energy rather than as a signal conductor in the normal sense of the word. They are capable of directing power precisely to where it is needed, can handle large amounts of power. A waveguide assembly may have a large number of brazed joints; this makes Cu-DLP ideal for this application since because it is deoxidised with phosphorus there is no problem with steam (hydrogen) embrittlement.

Waveguide (Courtesy of Amari Precision Tubes).

Quick facts

Properties

In the annealed (soft) to the hard condition the alloy has the following combination of properties:

- Tensile strength: 220-385 N/mm2

- Proof strength: 60-325 N/ mm2

- % Elongation: 55-4

- Hardness (HV): 45-155

- Electrical conductivity: 90-98% IACS

- Thermal conductivity: 350-365 W/m°C

Applications

- Cable strip

- Welded or brazed busbars

- Tubular busbars

- Lead frames for power semi-conductors

- Resistance welding equipment.

Available Forms

- Bar

- Extrusions

- Forgings

- Plate

- Sheet

- Strip

- Tube

- Wire

Comments

0 comments

Please sign in to leave a comment.