You’re most likely already familiar with the concept of recycling, and probably recycle paper, glass, clothing, shoes, aluminium drink cans and baked bean tins, but have you ever thought about recycling copper?

Brass bathroom taps, copper water pipes and electric cables all contain copper and are much longer-lasting and more valuable than any of the above. When these components eventually become available, possibly due to refurbishment or rebuilding, they are too valuable to be dumped in the bin or thrown into skips, ending up in landfill. They too can be recycled and the recovered copper used to make new products which will have the same properties as those made from ‘virgin’ copper that has been newly mined and refined.

Recyclability is one property that helps to establish the ‘green credentials’ of a material, which is to say how environmentally friendly it is.

Demand for copper, along with other metals such as steel, aluminium and nickel, is growing as countries throughout the world continue to develop industrially with a consequent requirement for more raw materials. To help conserve the world’s raw materials, there is a growing emphasis on recycling, however, for a more meaningful ‘green’ rating, a material’s sustainability needs to be considered.

The widely-accepted description of sustainability is the concept of meeting present needs without compromising the ability of future generations to meet their own needs.

A complete explanation of sustainability is beyond the scope of this e-source, however some environmental aspects of sustainability, such as energy conservation and reduction in landfill, and some social aspects such as maintenance of public health are considered.

Copper is a metal that is naturally present in the Earth’s crust, is essential to the development of all forms of life and has been a vital metal in the development of civilisation. It is the oldest metal used by man – the first copper coins date from 8700 BC – and, alloyed with tin, it forms the first alloy ever used, called bronze.

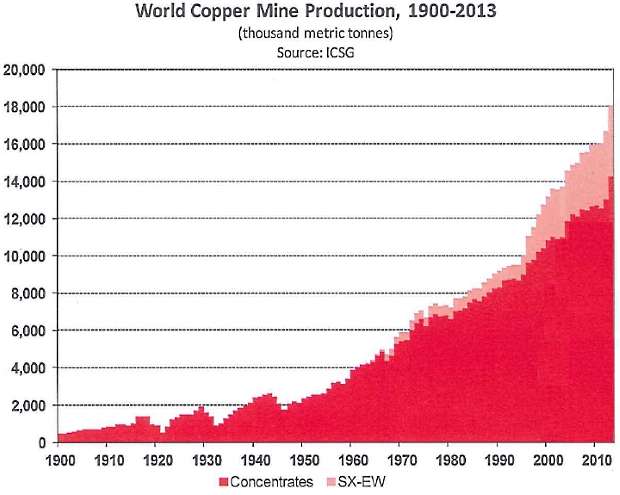

The total global demand for refined copper in 2013 was approximately 21 million tonnes.

Copper comes from two sources:

Primary sources

Mining of the raw material is called ‘primary production’. This is split between sulphide copper ore concentrate that is smelted and Solvent Extraction-Electrowinning (SX-EW) of oxide ores. SX-EW uses the sulphuric acid produced by smelting of sulphide ores. (See Copper Mining and Extraction: Sulphide Ores and Copper Mining and Extraction: Oxide Ores.)

Finished copper. (Courtesy of Aurubis.)

Secondary sources

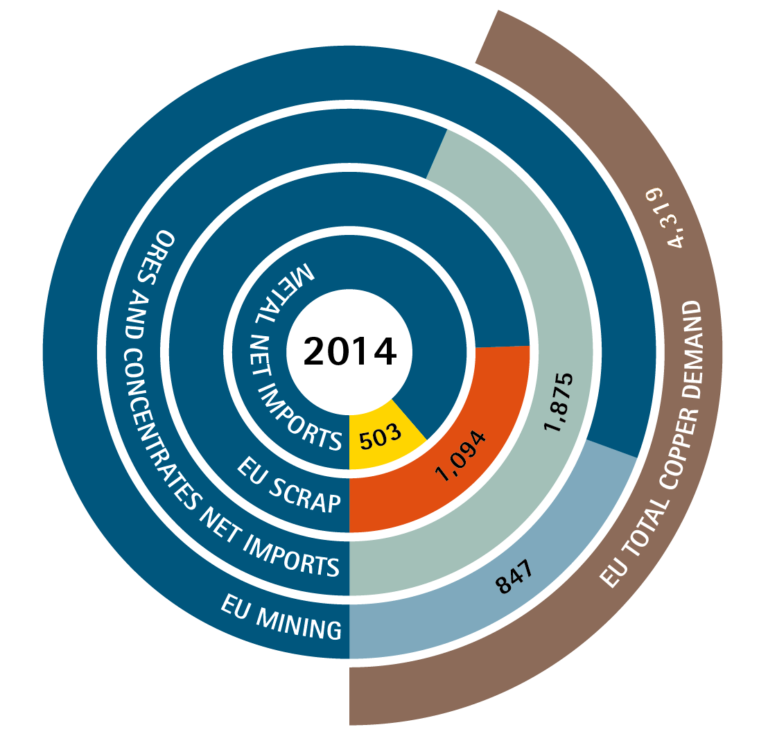

To cover the total annual copper demand of around 4 million tonnes, the European copper industry sources its materials in four ways:

- Mining operations in the European Union (20%)

- Domestic and industrial scrap from within the EU (43%)

- Imports of ores and concentrates (25%)

- Metal net imports from other regions (12%)

Process scrap, or ‘new scrap’, comes directly from manufacturers

and has a very high value. (Courtesy of Aurubis.)

End of life scrap is often combined with solder, plastics and other metals, making it more costly to recover. The amount of this type of scrap is rising dramatically as governments ban disposal in landfill or by incineration. Metals recovered from this scrap include gold, platinum, silver and rare earth metals such as neodymium.

The diagram below shows copper tonnage split (in millions) by source, for the year 2014. You can see that scrap recycling is an essential element. Increasing the amount of copper recovered from scrap will have a big impact on copper producers, reducing their energy use.

Figure 2: Copper tonnage by source for 2014. (Courtesy of International Copper Study Group and International Wrought Copper Council.)

Watch a video containing facts and figures about modern copper recycling:

Comments

0 comments

Article is closed for comments.