>> Download publication: Copper Alloys for marine Environments

>> Download publication: Copper Alloys in Seawater: Avoidance of Corrosion

>> Download publication: Copper-nickel Welding and Fabrication Guide

The addition of nickel to copper improves strength and corrosion resistance without reducing the good ductility. Copper-nickel alloys have excellent resistance to marine corrosion, strength and durability.

The two main alloys are 90/10 (90% copper, 10% nickel) and 70/30 (70% copper, 30% nickel). The 70/30 is the stronger and has greater resistance to seawater flow, but the 90/10 will provide good service for most applications and, being less expensive, tends to be more widely used. Both alloys contain small but important additions of iron and manganese which have been chosen to provide the best combination of resistance to flowing seawater and to overall corrosion.

Copper-nickel alloys are widely used for marine applications due to their excellent resistance to seawater corrosion, their ease of fabrication and their high inherent low susceptibility to the attachment of marine organisms. They have provided reliable service for several decades whilst offering effective solutions to today’s technological challenges.

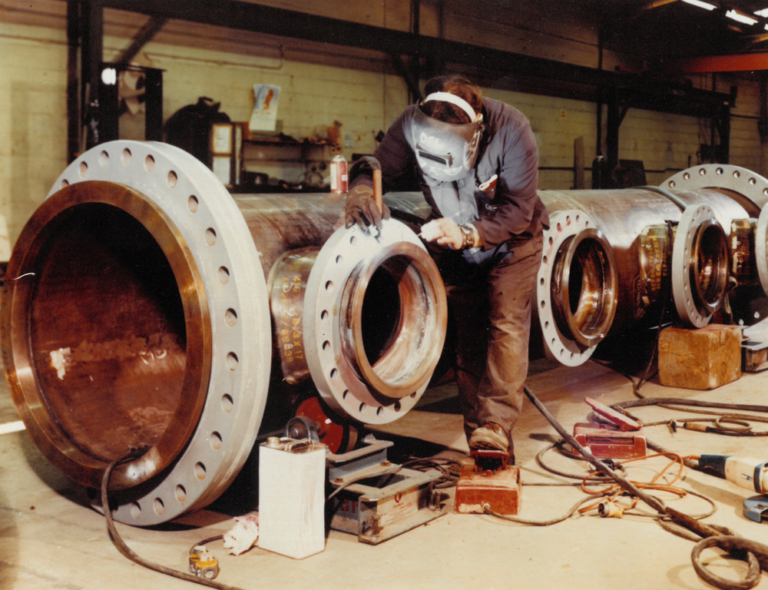

90/10 copper-nickel inlet/outlet manifolds for a seawater filtration unit (Courtesy IMI Dreh Ltd)

Applications

- Seawater pipework

- Offshore fire water systems

- Heat exchangers and condensers

- Sheathing of legs and risers on offshore platforms and boat hulls

- Hydraulic lines

- Fish cages for aquaculture

- Desalination units.

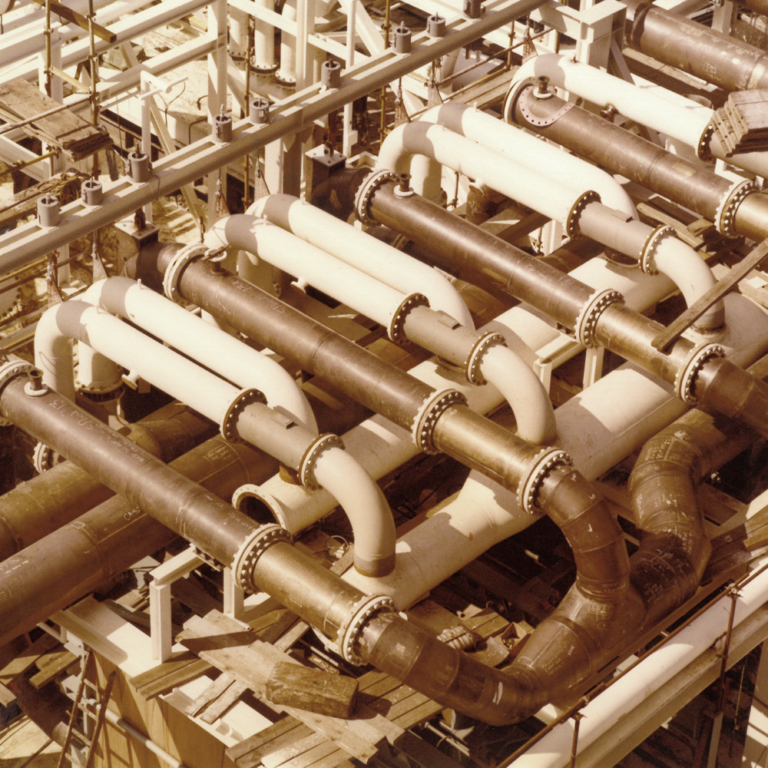

90-10 copper-nickel pipework in a seawater cooling line on an offshore gas platform (Courtesy IMI Dreh Ltd)

Copper-nickel Fabrication Guide

This publication provides an understanding of the two primary copper-nickel alloys to allow good fabrication and operational practices. Topics covered include general engineering properties of 90/10 and 70/30 copper-nickels, welding and fabrication practices and a basic overview of corrosion and other properties beneficial for marine environments.

Download the Copper-nickel Fabrication Guide

Training Videos on Welding of Copper-nickel

- Cleaning and preparation for welding of copper-nickel alloy

- TIG welding copper-nickel alloy

- Pipe welding copper-nickel alloy

- Shielded metal arc welding copper-nickel alloy

- Pulsed MIG welding copper-nickel alloy

Comments

0 comments

Please sign in to leave a comment.