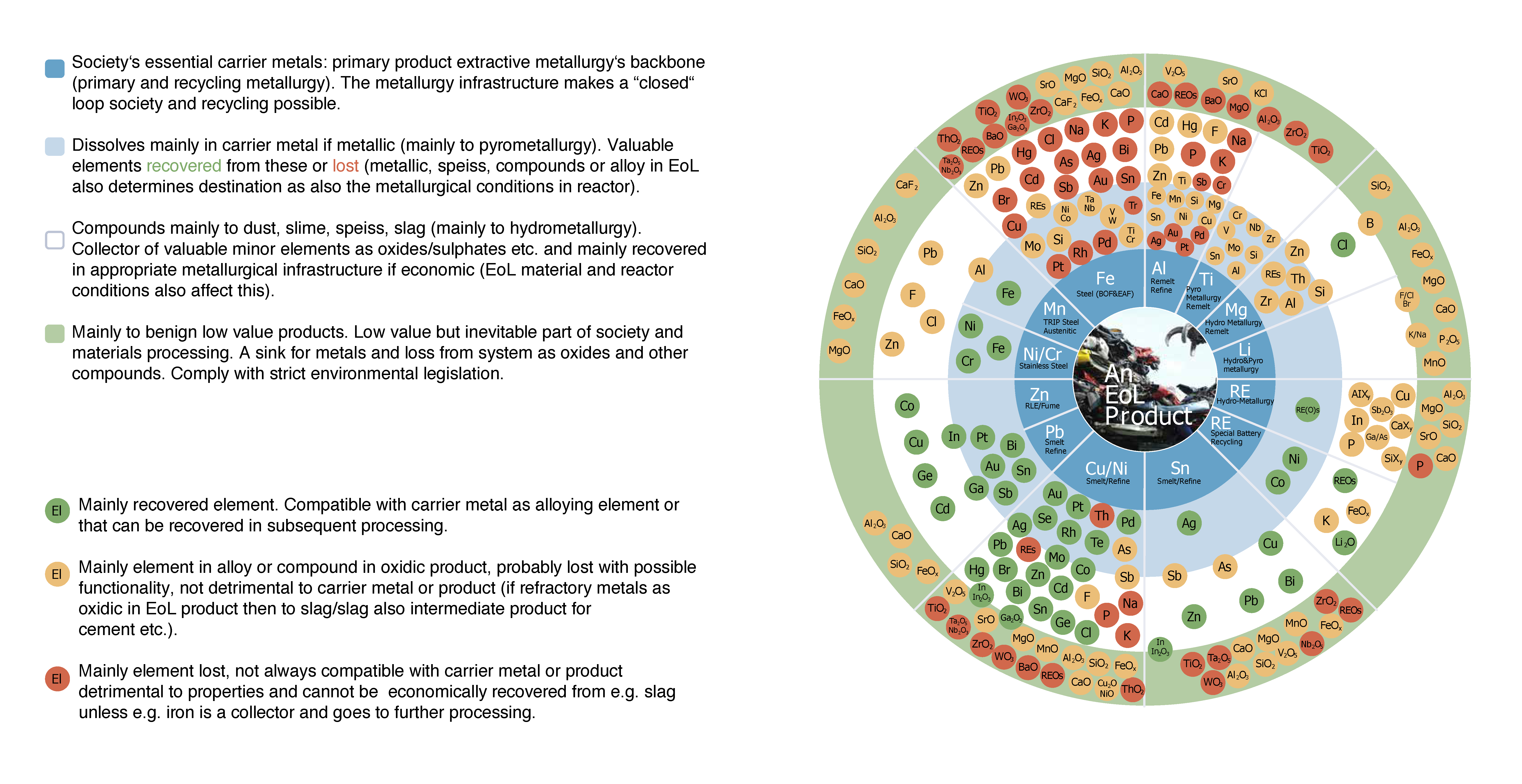

The metal wheel [UNEP - p 30] reflects the destination of different elements as a function of interlinked metallurgical process technology. Each slice represents the complete infrastructure for carrier metal refining. Consumer electronics contain over 40 different metals. This complexity of consumer products requires an industrial ecological network of interlinked metallurgical production infrastructure to maximize recovery of all elements in end-of-life products.

For copper, the metal wheel represents current recycling practice which provides an effective recovery route today for a range of by-products (minor and precious metals). These by-products are generally indistinguishable for metals obtained from primary sources. This positions copper uniquely relative to other carrier metals where alloying elements generally remain with the main metal, as in the case for example for iron or aluminium.

In addition, 80% of copper is used in its unalloyed form and can be fully recycled or even upcycled. The remaining ~ 20% is used in a complex mix of over 400 alloys. Some major alloying elements such as lead, tin or zinc can be removed effectively if required.

Copper's electrochemical properties, the metal wheel, copper's primary use as a conductor and the highly internlinked systems of smelters in place are all factors to position the copper industry well for the upcoming challenges of processing increasingly complex end-of-life waste streams in an increasingly circular economy.

-----

References

- Metals Recycling: Opportunities, Limits, Infrastructure. UNEP & International Resources Panel. 2013. https://wedocs.unep.org/handle/20.500.11822/8423 (accessed August 2021)

- https://www.chemistryworld.com/features/smartphone-recycling/2500497.article (2017 – checked October 2018)

- https://www.youtube.com/watch?v=CWt36I8JgVQ (2011 – checked January 2020)

-----

Last update: December 12, 2021

Comments

0 comments

Please sign in to leave a comment.