Aquaculture is a $100 billion global industry that supplies almost half the world’s demand for fish and is the fastest growing animal-food producing sector worldwide. To farm fish at sea you need pens made from netting.

Aquaculture pens can be close to shore, or in deep water offshore locations. (Courtesy of Cermaq.)

Aquaculture is a huge global industry. It has boosted the demand for marine biologists, engineers and technical staff. (Courtesy of Cermaq.)

Deep water pens have less environmental impact but are harder to work on. (Courtesy of Predomar.)

Biofouling

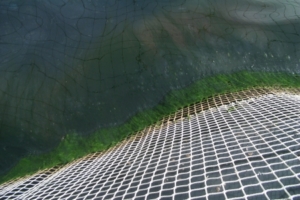

Biofouling is the adhesion of slime algae, sea mosses, sea anemones, barnacles and molluscs (oysters and mussels) on surfaces of marine structures. Biofouling becomes a problem when it places a drag on structures and blocks the inside of piping.

Looking down into the water you can see marine plants growing on this nylon netting. This is called biofouling and is a big problem for aquaculture.

Aquaculture nets made from polymers such as nylon are susceptible to biofouling, which reduces the flow of fresh seawater through the pens. This then becomes a breeding site for harmful parasites such as skin flukes and sea lice. It also makes the nets hundreds of times heavier so that they must be cleaned before lifting out of the water.

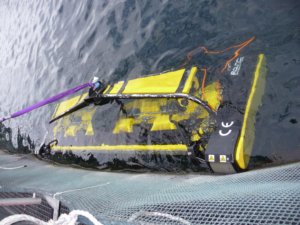

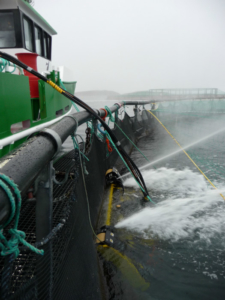

The industry spends millions every year keeping nets clean with expensive pressure washers. Some of these are remotely operated from ships and some by divers.

A remotely operated net cleaner. (Courtesy of Multi Pump Innovation.)

A support ship operates a remote control net washing machine. Cleaning is an expensive operation. (Courtesy of Aurora.)

Parasites can attach themselves to the fibres of the netting and then infect the fish. Predators can tear the netting, eating some fish and allowing others to escape.

Rope nets can be torn by predators and encourage biofouling. This diver is repairing a tear in the net. (Courtesy of oceanografica.com.)

Historical Uses of Copper

Copper alloys have a long history of being used to prevent the attachment of marine organisms. Cladding of wooden ships with copper or copper alloys has been known to prevent such attachment for many centuries.

Below is the restored Cutty Sark in Greenwich. The hull is clad in a copper alloy called Muntz metal (60% copper and 40% zinc). This stopped the attachment of barnacles and seaweeds to the hull, which would slow down the ship and need frequent scraping off, meaning the ship could travel faster, delivering goods in less time and improving profits for the company.

Hull of the restored tea clipper, Cutty Sark, clad with Muntz metal, originally fitted to prevent marine organisms attaching and optimise speed. (Wikimedia CC Cmglee.)

Copper Alloy Nets Produce Healthier Fish

Copper’s low susceptibility to marine organism attachment is as relevant today, for example, to prevent blocking of water intake pipes for power plants by zebra mussels and to increase yields for aquaculture.

Copper alloys inherently resist such attachment, without any special treatments or additions. Many polymer nets are treated with biocides to give this effect, however the chemicals are typically depleted within 13–32 weeks; after which time they need to be removed for cleaning regularly.

Cleaner nets mean faster flowing water with higher oxygen levels, which leads to lower levels of parasites and pathogens. The result is healthier fish that grow faster and need fewer antiobiotics.

The copper alloy nets are stronger and so resist storm damage and predator attacks. At the Mozambezi Tilapia Fish Farm in the Cahora Bassa Lake in Mozambique, the fish farmers report that the copper alloy nets are crocodile, shark and otter proof.

Although aquaculture is a relatively new industry in Sub-Saharan Africa, significant growth and adoption of technologies are helping to feed many in the region. Sub-Saharan Africa has the world’s highest population growth and is also the world’s hungriest region. Fish are (where available) the prime source of protein for many. However, natural fish resources are becoming depleted through overfishing. The gap between supply and demand can only be met by successful development of the fish farming industry.

Copper alloy nets offer a longer life, cheaper and less frequent cleaning and can ultimately be completely recycled, rather than simply thrown away.

Research into the benefits of copper alloy nets is ongoing.

The image above shows copper alloy mesh being made into pens in Greece by the aquaculture company Nireus. This is part of a global research programme to test copper alloy mesh pens. (Courtesy of Nireus.)

The above image shows mesh panels being joined together with copper alloy wire. Parasites find it hard to attach themselves to the smooth alloy surface. The alloy used for the mesh is a type of brass. Brass is strong, but malleable, allowing the wire to be bent into complex shapes.

A copper alloy mesh pen ready for lowering into the water in Greece. The clean alloy mesh allows maximum flow of fresh seawater through the pen. The strong mesh protects the fish from predator attack and escape as the mesh is much stronger than fabric or polymer netting. (Courtesy of Nireus.)

Questions and Activities

These open-ended questions can be used as group activities.

1. How can biofouling of netting affect the fish inside an aquaculture pen?

2. What advantages could copper alloy mesh pens have for aquaculture?

Research into Aquaculture

Aquaculture is an industry of huge global importance. Research the largest aquaculture companies and find out what scientific careers it can offer worldwide.

|

|

Comments

0 comments

Please sign in to leave a comment.